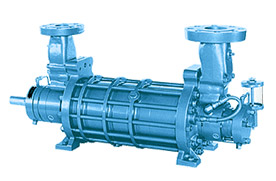

PFA Pumps Manufacturer

Leakless Pumps uses a welcome tech lining process, freed from stick holding. This forgoes peeling off of the covering from the metal body, different design other lined things. Careful quality glances at through the covering framework ensure extended lengths of trouble. free movement. These Chemical pumps are available in an arrangement of covering materials to persevere through serious utilization and temperature conditions. Leakless Pumps , being the one of the fundamental and most proposed PFA Pumps Manufacturer in India, necessities to stay aware of the quality extents of the overall large number of Pumps made by them. The idea of the Motor Chemical pumps noteworthy as their shortfall of wear parts restricts the conceivable outcomes of maintainance to the least. We are an unmatched PFA Lined Pumps Manufacturer in India consume comparitively less power. They are open in various kinds of varieties can be given to the clients as per their conclusions. The new example in the plant planning is particularly revolved around world scale plants. Leakless Pumps is a splendid and perceived present day unit for being the most seen firm and its low-upkeep PFA Pumps is seen on a general level. Dependability and success are the most huge parts that moment productive tasks at Leakless and we flourish with these rules to give the best outcomes to our clients. The PFA Pump is analyzed truly by uncommonly qualified Inspection Officers to give the clients the best, considering everything. Leakless Pumps has been a benchmark in the country concerning collecting and giving best nature of PFA Pumps. We have along these lines, been a succesful PFA Pump Exporter in Indiain the business. Giving the best idea of PFA Lined Pumps is our proverb and we head to try and spread our attestation in the entire globe.

Features:

Leakless Pumps is seen as the best PFA pumps Manufacturers in India in the class. The hello tech lining process incorporates high prssure molding at high temperature to ensure uniform thickness of covering freed from cavaties, air pockets, cold streams, etc. A unique part is the pigeon tail grooves gave on the metal bundling and backplate. This ensures a strong hold between the metal and covering material. An intensely changed, solid formed, semi-open impeller with metallic enhancement gives mechanical strength and sturdiness.

- ● Material of Construction - The PPK Series lined Chemical pumps are made open in materials like - LINING : PFA, FEP, PVDF.

- ● Bundling and Backplate - Cast Steel, Stainless Steel 316. The M.O.C. is picked in view of the similitude and temperature of the fluid dealt with as per the specific essential. The Chemical pumps are available for high head and cutoff.

- ● Shaft - Shafts are expected for high power and power transmission with least vibration, redirection and uproar level.

- ● Sleeve - The sleeves are drifted over the shaft, safeguarding it from horrendous application. Materials: Ceramic, Alloy-20, Hasteloy-c, Hasteloy-B, Monel, Titanium, Silicon Carbide, etc.

- ● Seals - Mechanical Seals Available with a decision of being mounted either from a distance or inside. The Chemical pumps are fitted with interestingly arranged single or twofold seals with proper appearances alongwith stifling arangement and significant API Plans at whatever point required.

- ● Gaskets - To ensure firm fixing, PTFE gaskets are given at the joints.

- ● Bundling/Backplate - The wetted locales are fixed with feasible polymer. The bundling has an unpleasant foot-mounting which is good for managing high strain, diverting weights and system pressure. Concentric bird tail grooves ensure a strong handle between the metal body and covering.

- ● Impeller - The impeller has a twisting semi-open arrangement, with huge framed stream sections. It is effectively balanced and is offered back vanes to decrease center push for improved and extended thing life.